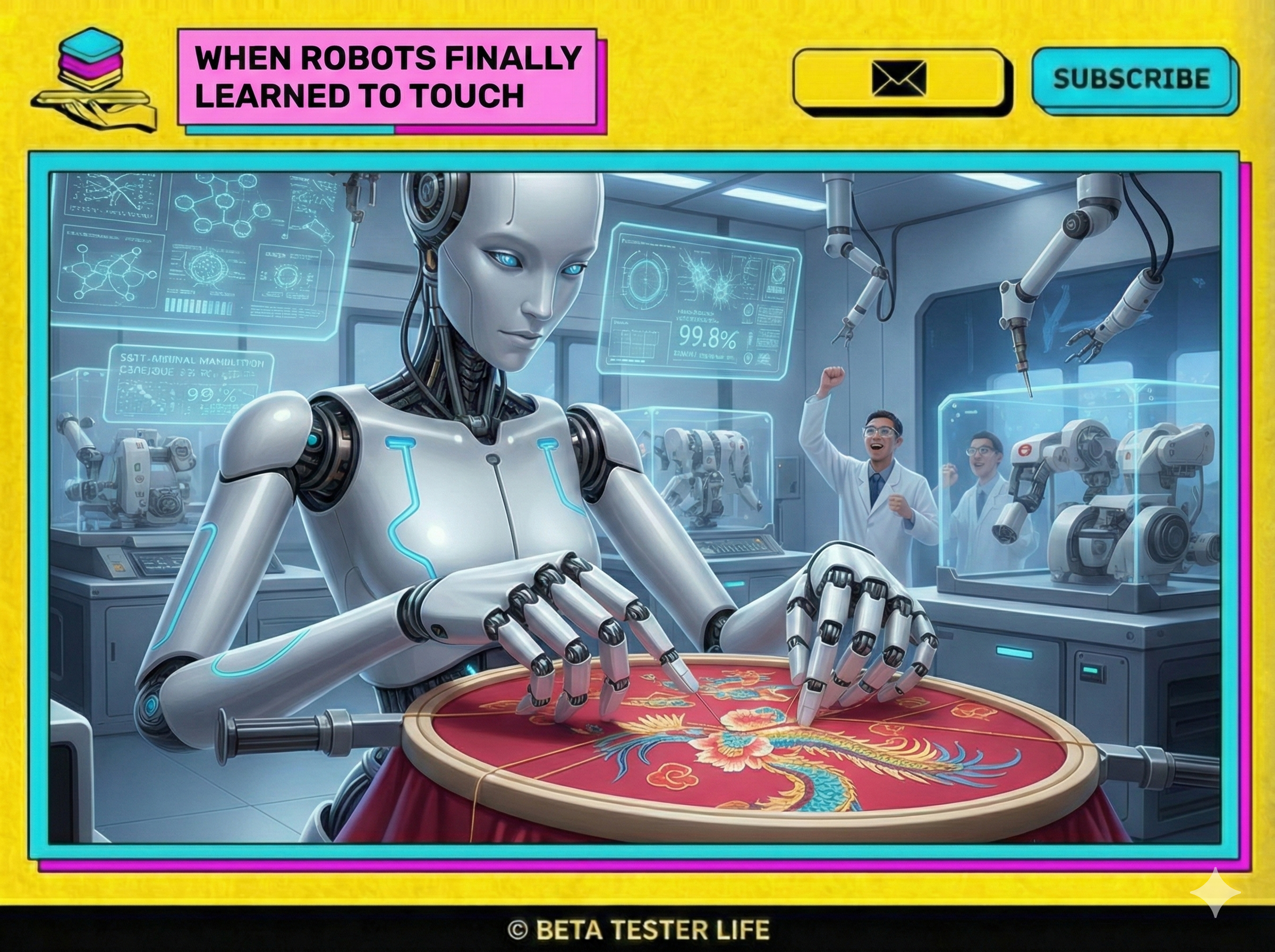

The Soft-Material Revolution: When Robots Finally Learned to Touch

For thirty years, one barrier kept skilled manufacturing jobs safe from automation. In 2025, that barrier fell. humanoid robot soft material manipulation

🎯 The Bottom Line

Humanoid robots can now manipulate soft materials—fabric, thread, wiring harnesses—with sub-millimeter precision. This isn’t incremental progress. It’s the removal of robotics’ most persistent limitation.

What Changed in 2025

| Capability | Before 2025 | Now |

|---|---|---|

| Material handling | Rigid only (metal, plastic) | Soft materials with precision |

| Hand coordination | Single-arm tasks | Two-handed simultaneous manipulation |

| Force control | Pre-programmed | Adaptive, real-time |

| Movement | Controlled walking | Fluid, human-like running |

The breakthrough: A Chinese humanoid robot stitched embroidery onto fabric using both hands simultaneously—a general-purpose machine executing fine motor control in real time. humanoid robot soft material manipulation.

The Convergence Effect

This isn’t about one breakthrough. It’s five technologies maturing together:

- Dexterous manipulation — sub-millimeter precision in soft material handling

- AI-driven perception — real-time environmental understanding

- Two-handed coordination — simultaneous bimanual tasks

- Adaptive force control — dynamic pressure adjustment

- Full-body sensory integration — 29+ degrees of freedom with feedback

Real-World Deployments Already Underway

📍 Border Security — UBTech’s Walker S2 humanoids now patrol China’s Guangxi province checkpoints ($37M government contract)

🏓 Dynamic Tasks — UC Berkeley’s HITTER plays extended table tennis rallies, requiring split-second timing and balance

🏃 Locomotion — Tesla’s Optimus progressed from walking to fluid running

🤖 Athletic Movement — EngineAI’s T800 brings 29 degrees of freedom for complex, unstructured environments

🔮 The Infrastructure Reliability Lens

What this means for enterprise planning:

| Sector | Impact Timeline | Risk Level |

|---|---|---|

| Textile manufacturing | 12-24 months | 🔴 High |

| Electronics assembly | 18-36 months | 🔴 High |

| Wiring harness production | 24-36 months | 🟡 Medium |

| Quality control/inspection | 12-18 months | 🔴 High |

Once humanoids can manipulate fabric, wiring, and fine assembly—entire categories of skilled labour become economically vulnerable to automation.

The Strategic Question

The question isn’t whether this transition accelerates.

It’s how quickly and in which regions it occurs.

Manufacturing facilities that once required experienced technicians for final assembly now have a credible technological substitute. The economic pressure to adopt will be immense.

🐕 Rocky’s Take

“Thirty years of ‘robots can’t do that’ just became ‘robots can do that.’ CTOs planning 3-5 year automation roadmaps need to compress those timelines. The soft-material barrier was the last major fortress—and it just fell.”

What’s your organisation’s exposure to soft-material automation? Drop a comment below or connect on LinkedIn.

📬 Subscribe to betatesterlife for weekly AI analysis with an infrastructure reliability lens. Frameworks over hype.

Sources:

- China’s New AI Robot Just Broke a Human Skill Barrier — YouTube

- Top 7 must-read humanoid robot stories of 2025 — Interesting Engineering